SECOND-HAND HULL. BRAND-NEW BOAT.

Every Kiwi Marine Repairs refit begins with a proven lifeboat hull and nothing else. These rescue-grade fiberglass hulls are stripped back, inspected, corrected where needed, and then rebuilt completely from the hull up.

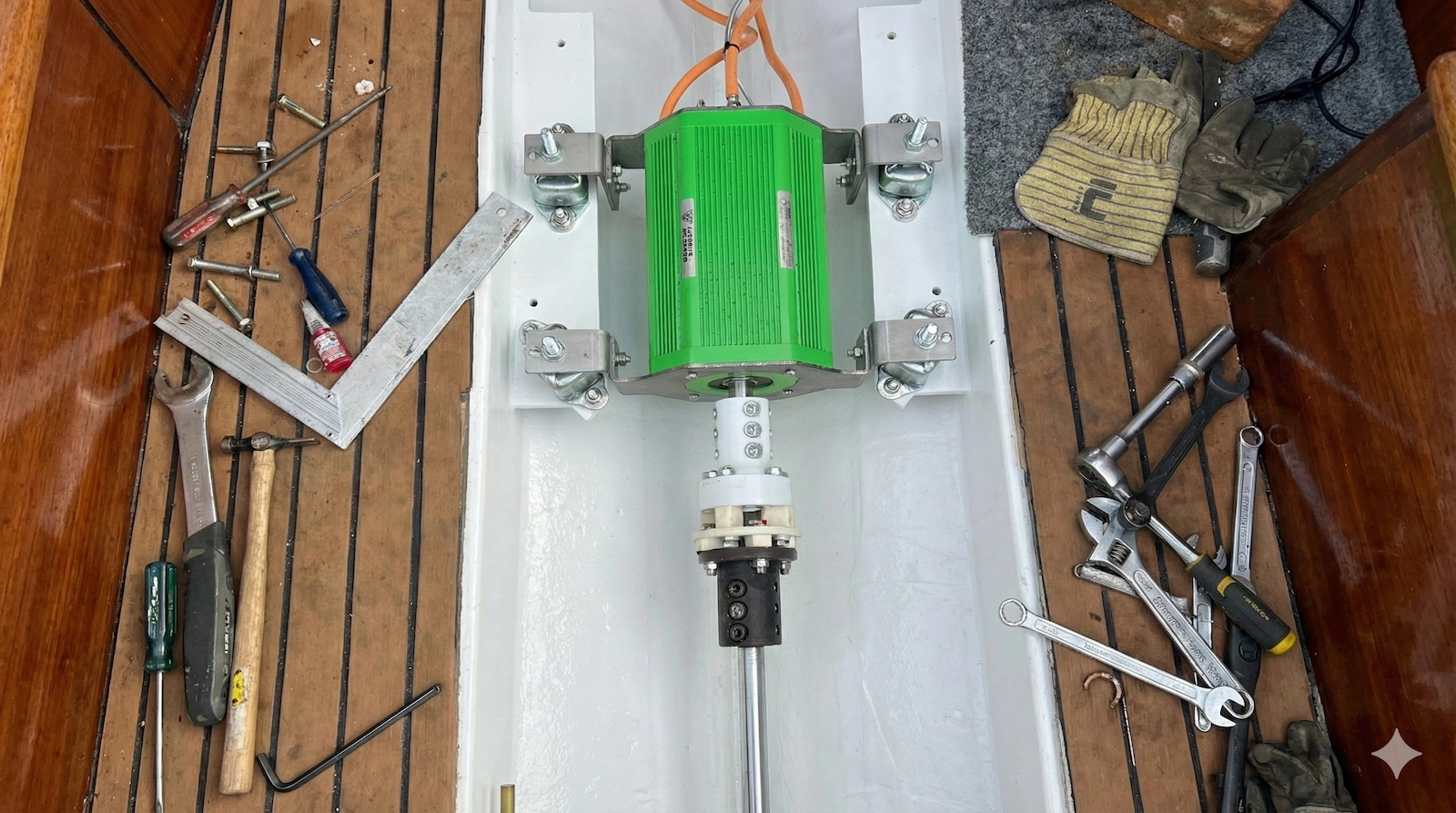

All mechanical systems, electrical systems, wiring, steering, and interior structures are newly engineered and installed as a single, integrated electric boat. What leaves the workshop is not a modified vessel or a simple engine swap, but a modern electric boat built on an exceptionally strong hull, designed for reliability, access, and long-term service.

Aerial view of the KMR850

Kiwi Marine Repairs builds complete electric boats in-house, carries out electric propulsion conversions on existing vessels, and supplies pre-engineered center console kits for clean, repeatable installations.

Remove the old diesel system, clean up the wiring chaos, and install a proper electric drivetrain using Green Marine components.

Learn more about electric conversions →

Waterproof fiberglass console modules built from KMR’s own mold, pre-rigged for electric conversions with sealed busbars, proper fusing, clean cable routing, and a protected controller compartment.

View console kit options →

A few examples of lifeboat refits and electric conversions completed in the last seasons.

Each KMR project starts with inspection, measurement, and a clear engineering plan. Systems are rebuilt from first principles: proper cabling, correct component selection, clean routing, and safe, accessible installs. The result is a vessel that’s easy to maintain and trust on the water.

Read the full story