ELECTRIC PROPULSION CONVERSIONS

Electric conversions engineered for predictable handling

We repower 5-12m boats with proper 48V electric systems built for real-world use. The engineering stays clean and accessible, with reliable components laid out for serviceability. Every conversion is tuned for Amsterdam waterways, duty cycles, and predictable handling.

5-12 m

Vessels

48V & 12V

Parallel electrical systems

From €15,900 incl. BTW

Indicative starting price for small diesel-to-electric conversions. Final pricing depends on vessel condition and specification.

Conversion service

Conversion planning, from assessment to water trial

Every conversion starts with an assessment of hull condition, weight balance, construction method, and how the boat is actually used. Each system is engineered around the specific vessel — from propulsion layout and component placement to custom battery enclosures where required to keep systems dry and serviceable. All work is carried out in-house and commissioned with dockside checks followed by a real-water trial.

IN DEVELOPMENT

Conversion Configurator

This tool will help estimate motor size, battery capacity, and layout recommendations based on your boat's dimensions and intended use. We're building it carefully using data from real conversions to ensure it provides accurate, genuinely useful guidance. It will be released once it meets our standards for reliability and precision.

When live, the configurator will provide:

- • Boat size → suggested motor range

- • Typical battery capacities for your use case

- • Use-case considerations (canals / rivers / light coastal)

If you're planning a conversion now, get in touch for a manual assessment.

Process overview

How a conversion runs

- 1. Assessment — hull condition, construction type, weight distribution, and how the boat is actually used.

- 2. System design — motor sizing, battery layout, charging strategy, cable routing, and fabrication of mounts, bulkheads, or watertight battery enclosures where required.

- 3. Installation — clean wiring, correctly sized fusing and isolation, and service-first component placement.

- 4. Commissioning — dockside checks, on-water trial, and a walkthrough to explain the system, operation, and basic care.

Pricing shown reflects a typical small-vessel conversion using an entry-level electric propulsion system. Battery capacity, fabrication work, shaft modifications, and auxiliary systems are specified per vessel and quoted separately where required.

Workshop snapshots

Real conversion work, step by step

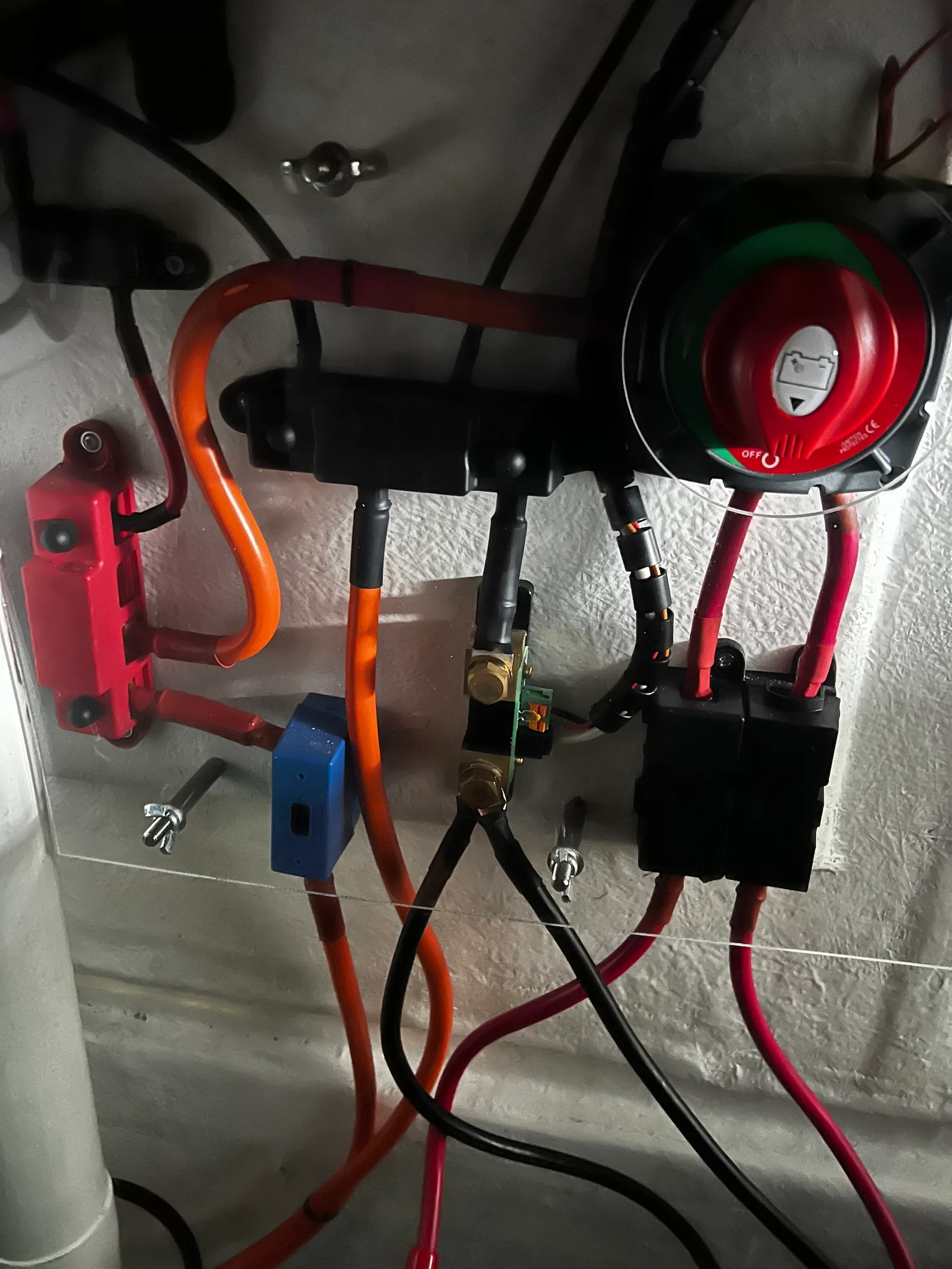

These are moments from real electric conversions — from engine removal and structural prep through to motor alignment, wiring, and final checks. Clean systems, correct installation, and serviceable layouts at every stage.

48V system install

Motor bed and alignment

Engine removal and cleaning

Wiring loom cleanup

Battery compartment layout

Final commissioning checks

Standard Inclusions

Every conversion includes the KMR method

Assessment, build quality, and commissioning stay consistent across every conversion.

- 🔍 Initial assessment, strip-out & usage review: Hull condition, existing systems, and how the boat is actually used. Includes removal of the old engine and cleanup of accumulated diesel or petrol residue from years of use.

- ⚖️ Hull inspection & mechanical layout planning: Battery placement, motor position, and practical fitment considerations — including modifying engine covers, beds, or surrounding structure where required.

- 🧱 Motor mounts, rails & driveline foundations: Fabrication or modification of motor rails, bulkheads, and structural supports as needed for Python Drive couplings or thrust-bearing setups.

- 🔌 Clean 48 V / 12 V system separation: Properly routed looms, labeled circuits, and clear separation between high-voltage and auxiliary systems.

- 📐 Correct cable sizing & routing: Marine-grade cabling sized for real loads, routed cleanly, supported properly, and protected from wear.

- 🛑 Main isolation, fusing & system protection: Correctly sized battery isolation, fusing, and protection installed at appropriate points in the system.

- 🧰 Service-first system layout: Access panels, logical component placement, and enough space to inspect, service, or upgrade the system later.

- 🔋 Secure battery installation & ventilation: Proper battery restraint, enclosure, and ventilation — no loose boxes, trapped heat, or cooked electronics.

- 🚤 Commissioning & on-water testing: Dockside checks followed by a real water trial to verify performance, temperatures, and system behaviour.

- 🤝 Handover walkthrough: In-person explanation of the system, controls, charging, and day-to-day operation — no mystery switches or guesswork.

Drive system

Green Marine motors

We use Green Marine for marine-specific reliability, clean integration, and known service performance.

Green Marine Motors

Green Marine Motors

We spec the motor, battery, and charging around your hull, use case, and budget.

GM5

- Power

- 5 kW @ 48V

- RPM

- 1200 RPM

- Torque

- 40 Nm

- Max boat length

- 7 m

- Max boat weight

- 1.5 t

GM7.5

- Power

- 7.5 kW @ 48V

- RPM

- 1200 RPM

- Torque

- 60 Nm

- Max boat length

- 10 m

- Max boat weight

- 3 t

GM10

- Power

- 10 kW @ 48V

- RPM

- 1200 RPM

- Torque

- 80 Nm

- Max boat length

- 10 m

- Max boat weight

- 5 t

GM17.5

- Power

- 17.5 kW @ 48V

- RPM

- 1200 RPM

- Torque

- 140 Nm

- Max boat length

- 15 m

- Max boat weight

- 10 t

GM22.5

- Power

- 22.5 kW @ 48V

- RPM

- 1200 RPM

- Torque

- 180 Nm

- Max boat length

- 20 m

- Max boat weight

- 20 t

GM35

- Power

- 35 kW @ 48V

- RPM

- 1200 RPM

- Torque

- 270 Nm

- Max boat length

- 25 m

- Max boat weight

- 25 t

Enquiries & availability

Ask about a conversion assessment, timelines, or commissioning slots.